Manufacturing on Your Desktop

The technology around desktop production of printed 3D objects is evolving rapidly. In the past year a number of systems have surfaced in the cheap segment of printing machines.

Where it only was the RepRap self built options, melting thermoplastics to layer the objects the year before, resin based systems below $2000 are becoming available.

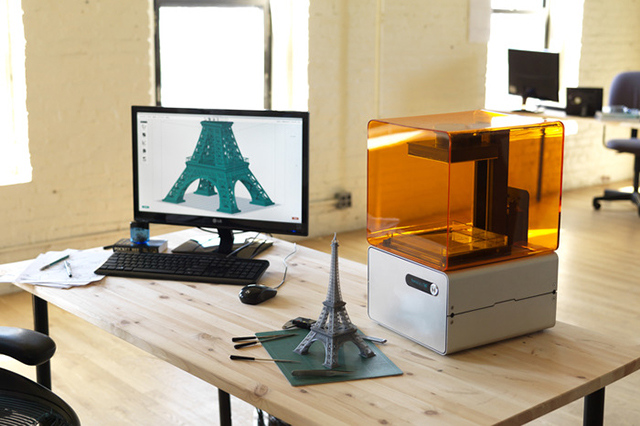

Image taken from kickstarter / The new Form 1 about to ship from April, although them lot ar sold out if you order now it will most likely be the May batch.

Image taken from kickstarter / The new Form 1 about to ship from April, although them lot ar sold out if you order now it will most likely be the May batch.

One of the market leaders in this very young segment is the Brooklyn based company MakerBot. Currently offering three versions of their Replicator printer. It work on a really good accuracy level for an attractive price. It brings the object manufacturing to your desk and can make a difference to your workflow if you are a designer.

Architecture has a big interest in the 3D manufacturing. As experts point out there is a gaping hole between the progress in software capacity and possibilities and the physical manufacturing capacities. This recent progress might start to close this gap for soem of the practices.

Especially in academia architecture has had an long standing interest in the 3d printing process. Many school have by now established a 3d manufacturing unit undertaking very interesting research towards the integration of processes in the workflow, but more importantly integrating 3d printing as part of the design process. For quick starters Makerbot offers also a platform to share 3d print object files. The Thingiverse is a great source not just for files to get you started but for discussion and advice, with each object has its own discussion channel and gallery of recreated objects. Usefull if you want to print your very own iPhone case, a filter lense case or working natilus gears.

Regarding precision a new 3d printer is about to come on the market developed and produced by formlabs. It is the result of one of the early large kickstarter projects. The team spent the past year developing and refining the design and the engineering oft he product and is now ready to ship them out by April this year.

This will be interesting to follow up and seeing the changes in practice these now available technologies bring to the everyday of designers, architects and engineers. It is great to see finally the shift back from virtual and digital modeling into the physical and real world. And here we have the potential for applications beyond the model oder visualisation objects, but for the production of working parts as actual pieces of our environment or in other words Printing the City as discussed in an earlier post.